From Jan to Nov 2025, Global[1] Electric Vehicle Battery Separator Installment[2] Reached 16,321Mil ㎡, a 41.2% YoY Growth

- With the increasing installment of

batteries in electric vehicles in 2025, the global separator market maintained

steady growth

(Source: 2025 Dec Global EV & Battery Monthly Tracker (Incl. LiB 4 Major Materials), SNE Research)

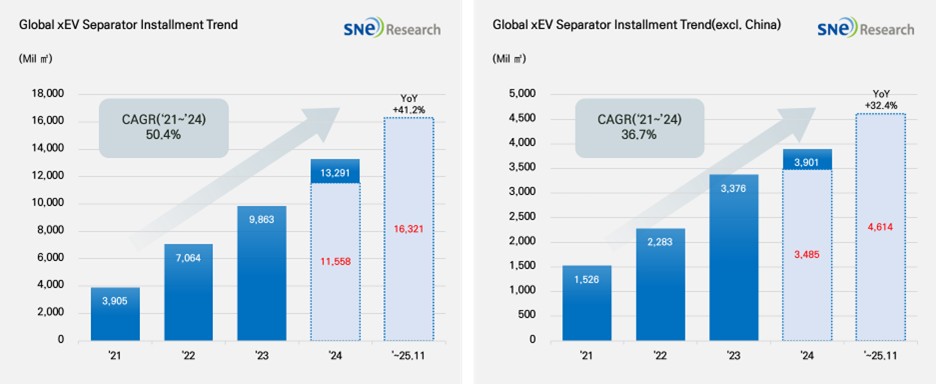

From Jan to Nov 2025, the total installment of separators used in electric vehicles (EV, PHEV, HEV) registered worldwide was approx. 16,321 Mil ㎡, posting a 41.2% YoY growth. During the same period, the total installment of separators in the non-China market was 4,614Mil ㎡, registering a 32.4% YoY growth and continuing to be in a stable growth trend.

Separator is a key material which physically separates cathode and anode inside lithium-ion battery but at the same time enables lithium ions to move freely, playing an important role in determining the safety and performance of battery. With increasing demand for high-performance batteries in accordance with expansion of electric vehicle market, the separator market indeed has been growing rapidly.

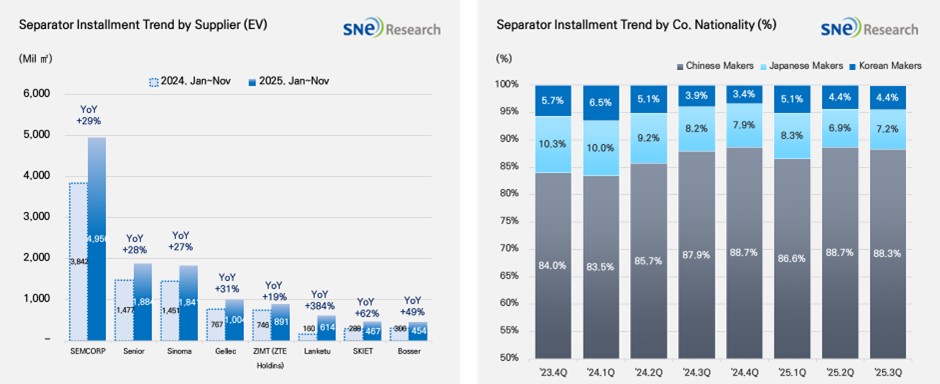

From Jan to Nov 2025, major separator suppliers showed notable growth in the global separator market. In particular, the installment of SEMCORP’s separator was increased by 29% from the same period last year, reaching 4,956Mil ㎡ and leading the market. Other major Chinese companies such as Senior(+28%), Sinoma(+27%), and Gellec(+31%) also continued to show strong growth in the market. Other than them, ZIMT and Lanketu also recorded a double-digit growth, increasing their shares in the market. Meanwhile, SK IE Technology from Korea also showed a 62% YoY growth, having 467Mil ㎡ of separator installed in EV batteries and exhibiting a steady growth.

In terms of market shares of companies by nationality, the Chinese separator makers accounted for almost 90% of the entire market share, boasting their dominance in the market. Since the 3rd quarter of 2023, the market shares of Japanese and Korean separator suppliers have been continuously dropping. In the 3rd quarter of 2025, the Japanese suppliers took up 7.2%, and the Korean companies accounted for 4.4% of the market share. As the market dominance by the Chinese suppliers have strengthened, the competition landscape has been further polarized between the Chinese makers and non-China companies in the global separator market.

(Source: 2025 Dec Global EV & Battery Monthly Tracker (Incl. LiB 4 Major Materials), SNE Research)

As the development of high-power and high-efficiency batteries accelerates, the global separator market is demanding higher thermal resistance and uniform quality. In response, major players are advancing their coating processes and expanding investments in high-speed production facilities. This trend reflects a shift toward a profitability-focused product portfolio and customized differentiation strategies, moving beyond simple capacity expansion.

As projects to strengthen regional battery supply chains continue in North America and Europe, separator companies are pushing for the establishment of sample test lines, expanded quality certifications, and joint venture discussions to enhance their responsiveness to local customers. Amid this growing trend of localization, signals of price hikes for wet-process separators originating from China have emerged. This highlights the possibility that the price and supply-demand cycles may once again be swayed by China, given the market's high dependence on Chinese suppliers.

Consequently, competitiveness in the separator market is shifting to be determined by technical maturity, supply stability, and regional response capabilities rather than mere production volume. For non-Chinese companies, it is effective to avoid competition in commodity products and instead strengthen their premium positioning centered on high-value segments—such as advanced coating, ultra-thin films, and high thermal resistance. Simultaneously, in North America and Europe, securing stable volumes through localized downstream process integration and long-term contracts is a viable strategy. In the mid-to-long term, companies that balance their customer base across various demand sources, such as EVs and ESS, are highly likely to expand their market share.

[2] Based on batteries installed to electric vehicles registered during the relevant period.