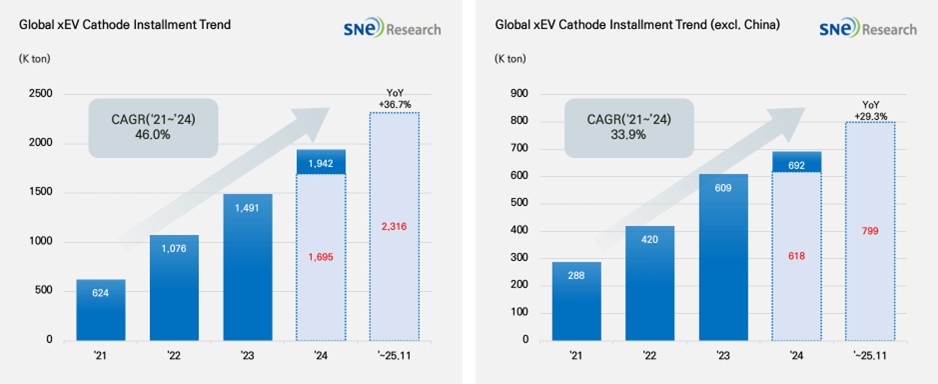

From Jan to Nov 2025, Global[1] Electric Vehicle Battery Cathode Material Installment[2] Reached 2,316K ton, a 36.7% YoY Growth

- From Jan to Nov 2025, EV battery cathode installment in

non-China market was 799K ton, posting a 29.3% growth

(Source: 2025 Dec Global EV & Battery Monthly Tracker (Incl. LiB 4 Major Materials), SNE Research)

From Jan to Nov 2025, the total installment of cathode materials used in electric vehicles (EV, PHEV, HEV) registered worldwide was approx. 2,316K ton, posting a 36.7% YoY growth. If we look at the market except China, the total cathode usage was 799K ton, and the growth rate was 29.3, which was steady and stable. Cathode material is a key material determining the capacity and output value of lithium-ion battery, upon which the performance of battery and driving range of electric vehicles depend. Currently, the battery market can be divided into the one centered around NCx ternary cathode material and the other mainly led by LFP cathode material, and both are driven by technical and economic advantages of each cathode material. Amidst the diversification of global cathode material demand, NCx ternary cathode material and LFP cathode material are positioning themselves as two main axes in the market.

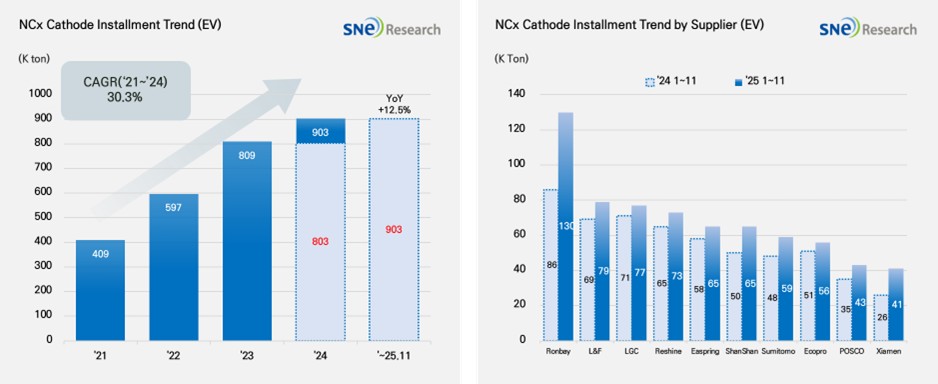

If we look at the market by different cathode materials, the installment of ternary cathode material during the relevant period was 903K ton, posting a 12.5% YoY increase and continuing a gradual growth. By company, Ronbay ranked top on the list. L&F(79K ton), Ecopro(56K ton), and POSCO(43K ton) all entered the upper rank, maintaining their reputation as leading Korean suppliers in the market. Overall, however, the growth of Chinese cathode material makers showed a noticeable growth. Major cathode suppliers such as Reshine, Easpring, and ShanShan are competing fiercely, and the Chinse cathode makers are gradually expanding their global market shares based on demand from the Chinese domestic market, price competitiveness, and their massive ramp-up plans.

(Source: 2025 Dec Global EV & Battery Monthly Tracker (Incl. LiB 4 Major Materials), SNE Research)

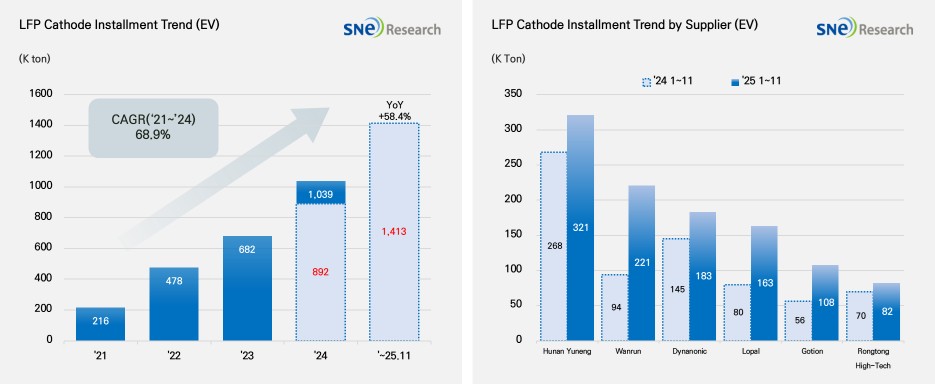

During the same period, the total installment of LFP cathode material was 1,413K ton, posting a rapid growth of 58.4% compared to the same period last year. In terms of growth pace, LFP cathode material surpassed that of ternary cathode material. Among the total cathode material installment, the proportion taken by LFP was about 60% (based on weight), meaning that the usage of LFP material has an increasing influence on the market. It is interpreted as being affected by the expansion of entry-level EV market in China, increasing preference to LFP chemistry with price competitiveness, and increasing adoption of LFP batteries by global OEMs. By cathode suppliers, Hunan Yuneng(321K ton) and Wanrun(221K ton) ranked 1st and 2nd on the list, while Dynanonic(183K ton) and Lopal(163K ton) ranked 3rd and 4th based on their growth higher than that of last year. Given the fact that the upper ranks are all taken by the Chinese companies, it is obvious that the LFP cathode material market is dominated by the Chinese companies. In turn, the growth of LFP cathode material market is directly connected to the reinforcement of global dominance by the Chinese material companies, which ultimately leads to solidify the China-centered structure in the global supply chain for battery materials.

(Source: 2025 Dec Global EV & Battery Monthly Tracker (Incl. LiB 4 Major Materials), SNE Research)

The cathode material market has reached a stage where it can no longer be explained solely by the demand ratio between NCM (ternary) and LFP batteries. As China strengthens its export control (licensing) systems over batteries, anode/cathode materials, and related equipment and technology, the criteria for material procurement are shifting. For cathode materials including LFP, factors such as customs lead times, contract stability, and the availability of alternative sourcing have become more critical than simple price competitiveness. This shift is driving a sense of urgency in North America and Europe to establish non-Chinese supply chains, particularly for localized Cathode Active Material (CAM) production

The environment remains complex from a raw material perspective as well. Lithium prices are showing signs of increased volatility again, driven by overlapping expectations for expanded power demand from both Energy Storage Systems (ESS) and AI data centers. Consequently, in 2026, the key factor distinguishing the performance of cathode material manufacturers is likely to be their ability to absorb rising raw material costs and manage margins, rather than simply the growth in electric vehicle sales itself.

It is also difficult to say that regulatory risks have been fully resolved. Although the enforcement date for critical raw material due diligence under the EU Battery Regulation has been pushed back to 2027, there is a high probability that 2026 will see an increasing number of cases requiring established traceability and verification systems. Ultimately, competitiveness in the 2026 cathode market is expected to be reshaped to include not only performance and cost but also how transparently a company manages its supply chain and responds to potential risks.

[2] Based on batteries installed to electric vehicles registered during the relevant period.