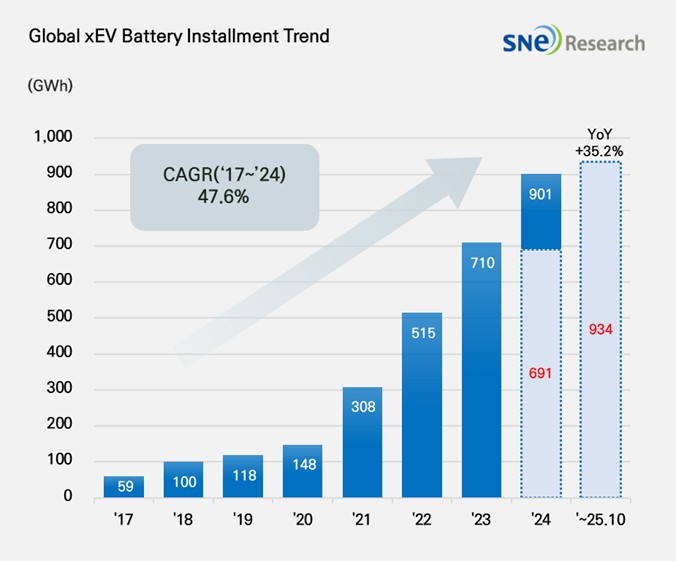

From Jan to Oct 2025, Global[1] EV Battery Usage[2] Posted 933.5GWh, a 35.2% YoY Growth

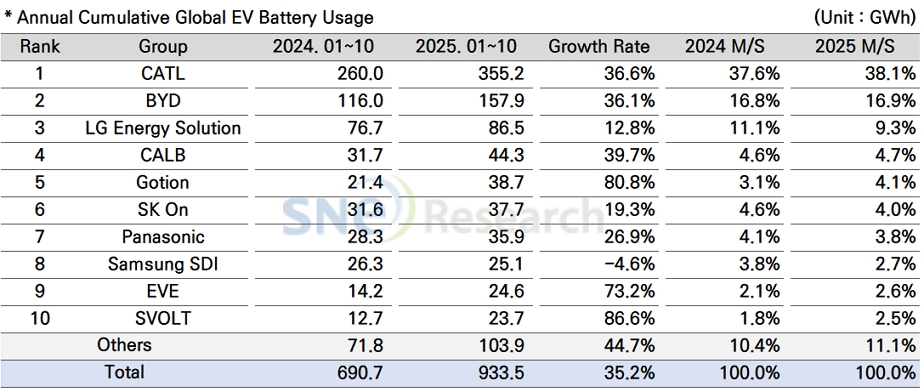

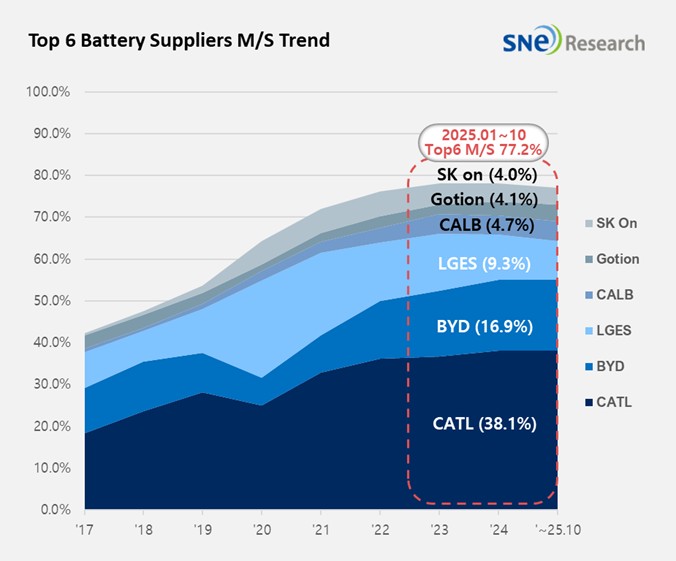

- From Jan to Oct 2025, K-trio’s M/S recorded 16.0%, a 3.5%p YoY decline.

From Jan to Oct 2025, the amount of energy held by batteries

for electric vehicles (EV, PHEV, HEV) registered worldwide was approximately 933.5GWh, a 35.2% YoY growth.

(Source: 2025 Nov Global Monthly EV and Battery Monthly Tracker, SNE Research)

The combined market shares of LG Energy Solution, SK On, and Samsung SDI in global electric vehicle battery usage from Jan to Oct in 2025 posted 16.0%, a 3.5%p decline from the same period last year. LG Energy Solution remained 3rd on the list with 12.8%(86.5GWh) YoY growth. While SK On ranked 6th with a 19.3%(37.7GWh) growth, Samsung SDI posted 4.6%(25.1GWh) degrowth.

(Source: 2025 Nov Global Monthly EV and Battery Monthly Tracker, SNE Research)

If we look at the usage of battery made by the K-trio in terms of the sales volume of EVs, Samsung SDI’s battery was mainly supplied to BMW, Audi, and Rivian. BMW has Samsung SDI’s batteries in its major electrified models such as i4, i5, i7, and iX. With the increasing sales of electric vehicles to which Samsung SDI’s batteries are installed, the installation volume of their batteries has also increased, accordingly. In case of Rivian, although they recorded stable sales of R1S and R1T in the US, the newly launched standard range trim, to which Gotion’s LFP batteries are installed, has had a negative impact on the share of batteries supplied by Samsung SDI to Rivian. In addition, a slowdown in sales of Rivian has also affected the usage of Samsung SDI’s battery in a negative way. Meanwhile, Audi’s Q6 e-Tron, built on the PPE platform and equipped with batteries of SDI and CATL, has been received well mostly in Europe.

SK On’s battery was installed to electric vehicles made by Hyundai Motor Group, Mercedes-Benz, Ford, and Volkswagen. Hyundai Motor Group has SK On’s battery in IONIQ 5 and EV 6 most. And the steady sales of VW ID.4 and ID.7 also contributed to an increase in the usage of batteries made by SK On. On the other hand, although Ford F-150 Lighting, to which large-capacity batteries are installed, saw a slowdown in sales, thanks to favorable sales of Explorer EV, the volume of batteries used in Ford’s electric vehicles has seen an 18.1% YoY growth.

LG Energy Solution’s battery was mainly used by Tesla, Chevrolet, Kia, and Volkswagen. Due to a slowdown in sales of Tesla models, to which LG Energy Solution’s batteries are installed, the usage of LGES’ batteries by Tesla saw a 14.5% YoY decrease. On the other hand, thanks to favorable sales of Kia EV 3 in the global market and expanded sales Chevrolet Equinox, Blazer, and Silverado EV, to which the Ultium platform was applied, in the North American market were regarded as a major drive behind the increasing usage of batteries made by LG Energy Solution.

Panasonic, which mainly supplies its batteries to Tesla, ranked 7th on the list with the battery usage of 35.9GWh. Panasonic has been focusing on the improvement of efficiency in its North American production lines as well as the development of next-gen 4680·2170 cells in order to lower its dependence on Tesla as a major client. The transition process in Kansas·Nevada plants has accelerated, bringing about stability in the cost structure. In addition, as it has been further deepening discussions on new cooperation opportunities with North American OEMs, the Japanese battery maker has been solidifying a foundation for client diversification. These efforts are expected to buffer any risks related to expansion of internal production and support maintaining its North American market share in the mid to long term.

CATL remained top in the ranking of global battery usage, posting a 36.6%(355.2GWh) YoY growth. Major OEMs such as ZEEKR, AITO, Li Auto, and Xiaomi have chosen CATL’s batteries for their EVs, and many global major OEMs like Tesla, BMW, Mercedes-Benz, and Volkswagen, have also adopted CATL’s batteries.

BYD took the 2nd position on the list with a 36.1%(157.9GWh) growth rate. BYD, which manufactures both batteries and electric vehicles (BEV+PHEV) in-house, has been expanding sales of various models based on its strong price competitiveness. It has been expanding its presence not only in the Chinese domestic market but also in the overseas market. In particular, BYD has boasted a noticeable growth in the European market. Between Jan and Oct 2025, BYD’s battery usage in Europe reached 11.2GWh, exhibiting a 216.4% increase year-on-year.

(Source: 2025 Nov Global Monthly EV and Battery Monthly Tracker, SNE Research)

By the end of 2025, the global EV battery market continues to experience demand growth, while shifts in regional policy environments and restructuring of technology strategies are making the competitive landscape increasingly complex. In North America, automakers are engaging in more long-term procurement agreements aimed at stabilizing battery costs and reducing supply risks. In Europe, efforts to ease the regional concentration of battery production are accelerating, with a growing shift toward local assembly and localized material sourcing. Asian manufacturers are pursuing product differentiation through high–energy-density cells, long-life platforms, and next-generation BMS technologies, while focusing on expanding partnerships with major OEMs. Amid these changes, battery companies face critical challenges not only in technological competitiveness and production scale, but also in building flexible supply chains capable of responding quickly to regional policy changes. Ultimately, after 2026, market competitiveness will be determined less by global expansion and more by the ability to operate strategic portfolios tailored to the regulatory, demand, and supply conditions of each region.

[2] Based on battery installation for xEV registered during the relevant period.