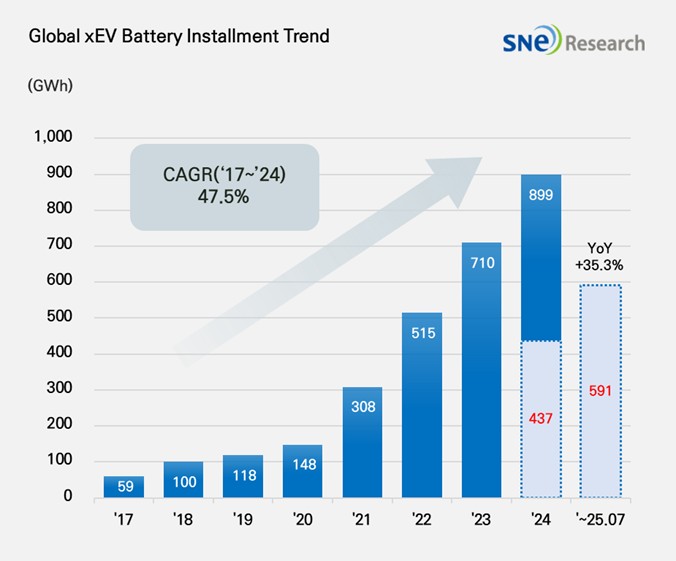

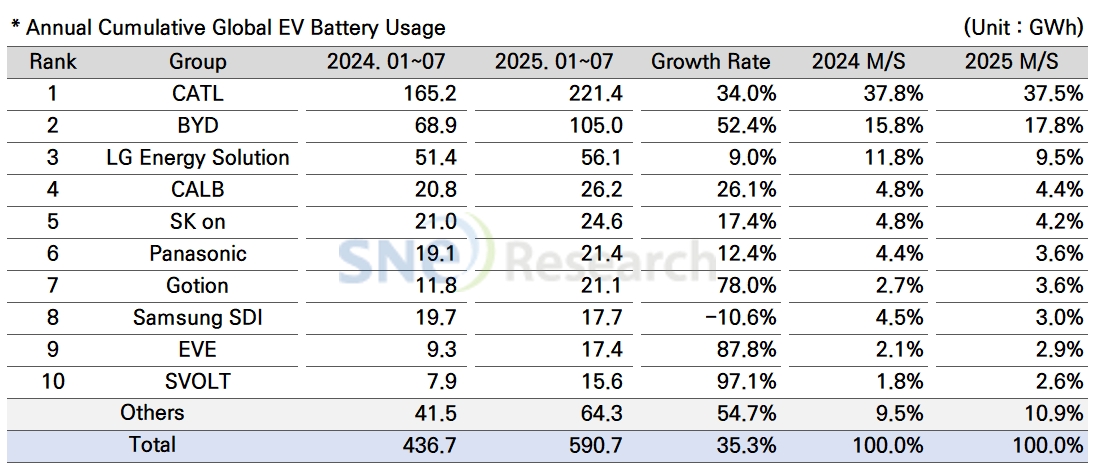

From Jan to July in 2025, Global[1] EV Battery Usage[2] Posted 590.7GWh, a 35.3% YoY Growth

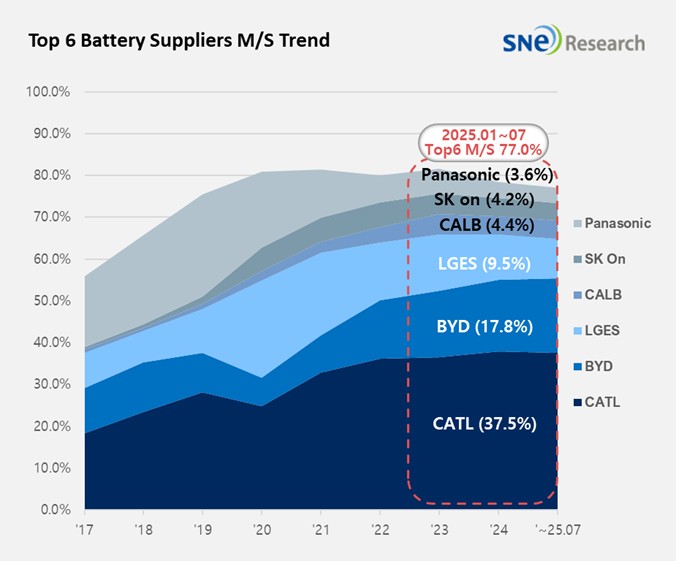

- From Jan to July in 2025, K-trio’s M/S recorded 16.6%, a 4.5% YoY decline

From Jan to July in 2025, the amount

of energy held by batteries for electric vehicles (EV, PHEV, HEV) registered

worldwide was approximately 590.7GWh,

a 35.3% YoY growth.

(Source: 2025 Aug Global Monthly EV and Battery Monthly Tracker, SNE Research)

The combined market shares of LG Energy Solution, SK On, and Samsung SDI in global electric vehicle battery usage from Jan to July in 2025 posted 16.6%, a 4.5%p decline from the same period last year. LG Energy Solution remained 3rd on the list with 9.0%(56.1GWh) YoY growth. While SK On ranked 5th with a 17.4%(24.6GWh) growth, Samsung SDI posted a 10.6%(17.7GWh) degrowth.

(Source: 2025 Aug Global Monthly EV and Battery Monthly Tracker, SNE Research)

If we look at the usage of battery made by the K-trio in terms of the sales volume of EVs, Samsung SDI’s battery was mainly supplied to BMW, Audi, and Rivian. BMW has Samsung SDI’s batteries in its major electrified models such as i4, i5, i7, and iX, and, due to a slowdown in sales of those models, Samsung SDI saw a 5.9% YoY decrease in the usage of batteries sold to BMW. Although Rivian recorded stable sales of R1S and R1T in the US, the newly launched standard range trim, to which Gotion’s LFP batteries are installed, has lowered the share of batteries supplied by Samsung SDI to Rivian. On the other hand, as Audi started selling Q6 e-Tron, built on the PPE platform, the usage of batteries recorded a 6.1% YoY growth.

SK On’s battery was installed to electric vehicles made by Hyundai Motor Group, Mercedes-Benz, Ford and Volkswagen. Hyundai Motor Group saw a gradual recovery in sales of IONIQ 5 and EV 6 after facelift, and steady sales of VW ID.4 and ID.7 also contributed to an increase in the usage of batteries made by SK On. Despite a slowdown in sales of Ford’s F-150 Lightning, the increasing sales of Explorer EV, E-Transit, and PUMA EV has led to a 12.9% growth in the usage of batteries made by SK On.

LG Energy Solution’s battery was mainly used by Tesla, Chevrolet, Kia, and Volkswagen. In case of Tesla, the overall decline in sales and particularly, a slowdown in sales of trims, to which LGES’ batteries are installed, have led to a 23.6% YoY decrease in the usage of batteries made by LG Energy Solution. On the other hand, thanks to favorable sales of Kia EV 3 in the global market and expanded sales of Equinox, Blazer, and Silverado EV, to which the Ultium platform was applied, in the North American market were a major drive behind the growth of usage of batteries made by LG Energy Solution.

Panasonic, which mainly supplies batteries to Tesla, ranked 6th on the list with the battery usage of 21.4GWh. Panasonic has been accelerating the reshuffling of supply chain in response to the recently fortified US tariffs on the Chinese batteries and raw materials. To be specific, Panasonic is trying to lower its dependency on the Chinese materials, expand the procurement of local materials, and secure new material sources in order to increase the stability in battery production. These efforts are expected to lay a significant foundation for recovery in the usage of batteries made by Panasonic and maintaining its market share in the North American market.

CATL firmly remained top in the ranking of global battery usage, posting a 34.0%(221.4GWh) YoY growth. Key Chinese OEMs, such as Changan, Geely, Seres, and Xiaomi, adopt CATL’s batteries, and many global major OEMs, including Tesla, BMW, Mercedes-Benz, and Volkswagen, are also using CATL’s batteries for their EV models.

BYD took the 2nd place with a growth rate of 52.4%(105.0GWh). BYD, which manufactures both batteries and electric vehicles (BEV+PHEV) in-house, has been expanding sales of various models based on its strong price competitiveness. It has been solidifying its presence not only in the Chinese domestic market but also in the global market. In particular, BYD showed a notable expansion in the European market. In the 1st half of this year, the usage of BYD batteries in Europe recorded 6.9GWh, a 260.7% YoY increase.

(Source: 2025 Aug Global Monthly EV and Battery Monthly Tracker, SNE Research)

As regulatory tightening and supply chain reorganization accelerate, particularly in the United States and Europe, the battery industry landscape is being restructured. The One Big Beautiful Bill Act (OBBBA) calls for an early phase-out of IRA benefits, a gradual reduction of AMPC incentives, and introduces the Foreign Entity of Concern (FEOC) rule to restrict subsidy eligibility for batteries and raw materials linked to China. As a result, companies are being compelled to revise their strategies to increase sourcing and manufacturing within North America. On the demand side, Europe is showing a gradual recovery due to stricter CO₂ regulations, while in the U.S., the market is showing a divergence; HEVs gaining momentum and BEVs slowing down amid subsidy and policy uncertainty. Given that policies are simultaneously impacting both prices and demand, the first step is to realign portfolios by deciding which models to build, where, and with which materials. Based on that, companies should integrate co-planning with OEMs, sign long-term raw material contracts, and coordinate localization schedules to optimize subsidies and cash flow.

[2] Based on battery installation for xEV registered during the relevant period.