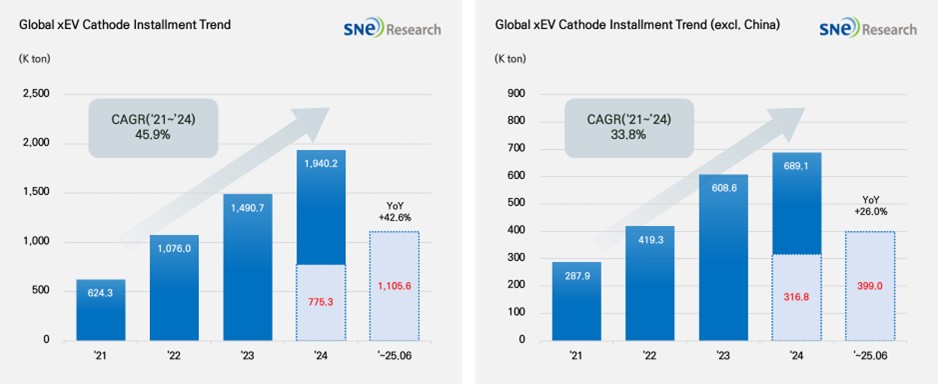

From Jan to June in 2025, Global[1] Electric Vehicle Battery Cathode Material Installment[2] Reached 1,105.6K ton, a 42.6% YoY Growth

- From Jan to June in 2025, EV battery cathode material

installment in non-China market was 399.0K ton, posting a 26.0% growth

(Source: 2025 July Global EV & Battery Monthly Tracker (Incl. LiB 4 Major Materials), SNE Research)

In H1 2025, the total installment of cathode materials used in electric vehicles (EV, PHEV, HEV) registered worldwide was approx. 1105.6K ton, posting a 42.6% YoY growth. In particular, the installment of cathode materials used in electric vehicles in the non-China market recorded 399.0K ton, showing a stable growth of 26.0%.

Cathode material is a key material determining the capacity and output value of lithium-ion battery, upon which the performance of battery and driving range of electric vehicles depend. Currently, the battery market can be divided into the one centered around NCx ternary cathode material and the other mainly led by LFP cathode material, and both are driven by technical and economic advantages of each cathode material. Amidst the diversification of global cathode material demand, NCx ternary cathode material and LFP cathode material are positioning themselves as two main axes in the market.

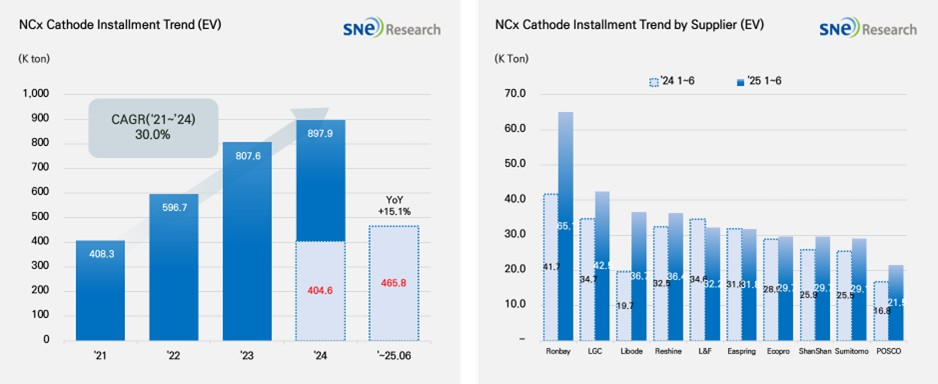

If we look at the market by different cathode materials, the installment of ternary cathode material during the relevant period was 465.8K ton, posting a 15.1% YoY growth and continuing a gradual growth. By company, Ronbay and LG Chem ranked 1st and 2nd on the list, leading the market, while Libode settled in the 3rd place with 36.7K ton based on the increasing demand for mid-Ni cathode material. L&F (32.2K ton), Ecopro (29.7K ton), and POSCO (21.5K ton) also entered the upper rank, maintaining their presence in the market. Overall, however, the growth of Chinese cathode material makers showed a noticeable growth. Major cathode suppliers such as Reshine, Easpring, and ShanShan are competing fiercely, and the Chinse cathode makers are gradually expanding their global market shares based on demand from the Chinese domestic market and their massive ramp-up plans.

(Source: 2025 July Global EV & Battery Monthly Tracker (Incl. LiB 4 Major Materials), SNE Research)

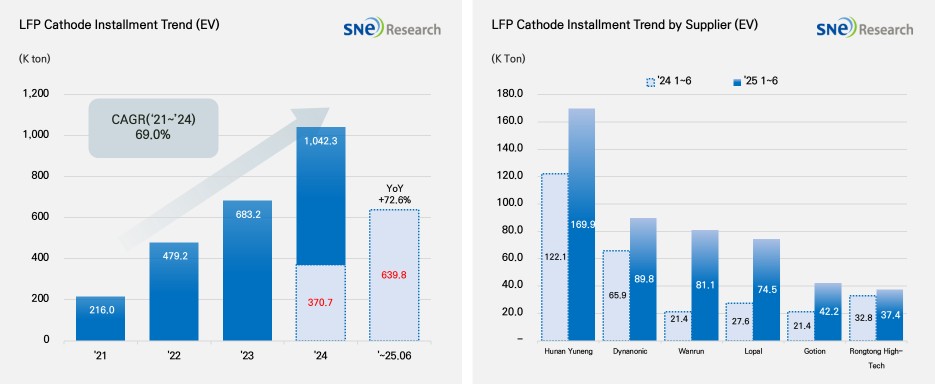

During the same period of time, the total installment of LFP cathode material was 639.8K ton, showing a massive 72.6% YoY growth. Among the total cathode material installment, the proportion taken by LFP was about 58% (based on weight), which was over half the entire market share. It proved that the influence of LFP chemistry and LFP cathode material has been further increasing in the market. It is interpreted as being affected by the expansion of entry-level EV market in China, increasing preference to LFP chemistry with price competitiveness, and increasing adoption of LFP batteries by global OEMs. By cathode suppliers, Hunan Yuneng (169.9K ton) and Dynanonic (89.8K ton) ranked 1st and 2nd on the list, solidifying their dominance in the market. Wanrun (81.1K ton) and Lopal(74.5K ton) settled in the 3rd and 4th places based on their growth which was more than two times that of last year. Other than these, Gotion and Rongtong High-Tech are expanding their market shares by supplying more than 40K tons per each. Those suppliers in the upper rank are all Chinese cathode makers, clearly showing that the LFP cathode market is practically dominated by China. In turn, the growth of LFP cathode material market is directly connected to the reinforcement of global dominance by the Chinese material companies, which ultimately leads to solidify the China-centered structure in the global supply chain for battery materials.

(Source: 2025 July Global EV & Battery Monthly Tracker (Incl. LiB 4 Major Materials), SNE Research)

Despite geopolitical risks and policy changes, the cathode material market has continued growth supported by expanded demand for two major cathode materials, LFP and ternary. LFP has been rapidly expanding its market share based on price competitiveness and increasing adoption of LFP batteries by major OEMs. Ternary batteries maintain its stable position based on demand for high-performance batteries mainly installed in premium EVs. The United States is maintaining high tariffs on Chinese-made batteries and materials, placing pressure on the restructuring of the North American supply chain. In response, material suppliers from countries outside China—such as South Korea and Japan—are expanding their presence in the North American market under favorable conditions, with some companies actively establishing local production bases.

Global materials companies are accelerating strategies to diversify product portfolios, broaden customer bases, and strengthen regional hubs as a response to trade risks and the concentration of supply chains. In the cathode materials market, China's tightening of technology exports is clashing with the localization demands of the U.S. and Europe, highlighting the strategic importance of South Korean companies, which offer both technological expertise and stable production capacity.

Looking ahead, demand is expected to grow around high energy density, long cycle life, and low-cobalt chemistries. Rather than supply overcapacity, the key competitive factors will likely be technological maturity and globally distributed manufacturing strategies.

[2] Based on batteries installed to electric vehicles registered during the relevant period.