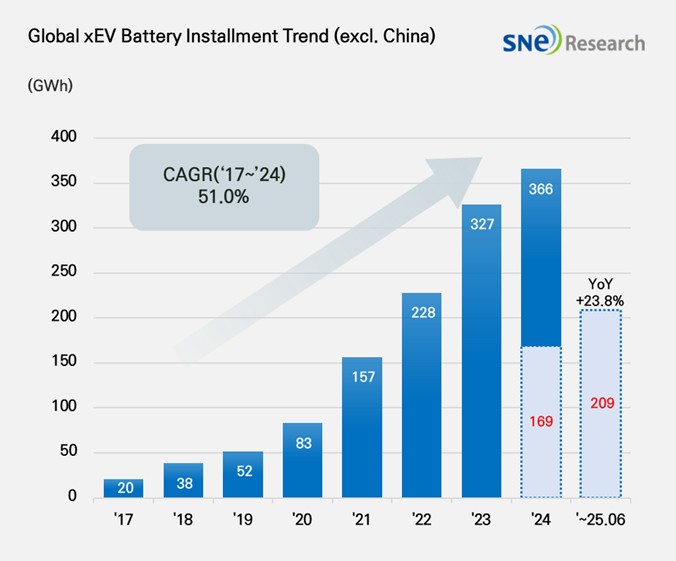

From Jan to June in 2025, Non-Chinese Global[1] EV Battery Usage[2] Posted 209.2GWh, a 23.8% YoY Growth

- From Jan to June in 2025, K-trio’s combined M/S recorded 37.5% (except China market)

Battery installation for global electric vehicles (EV,

PHEV, HEV) excluding the Chinese market sold from Jan to June in 2025 was

approximately 209.2GWh, a 23.8% YoY growth.

(Source: Global EV and Battery Monthly Tracker – July 2025, SNE Research)

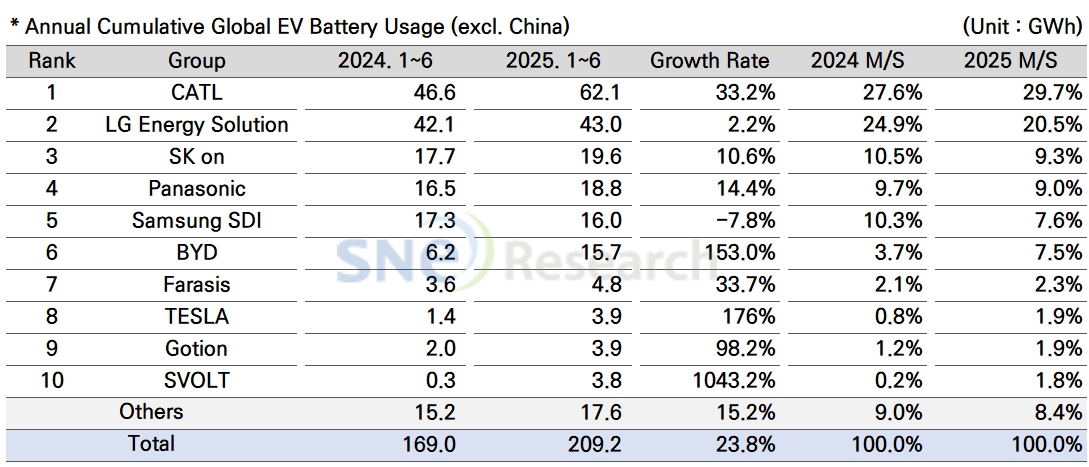

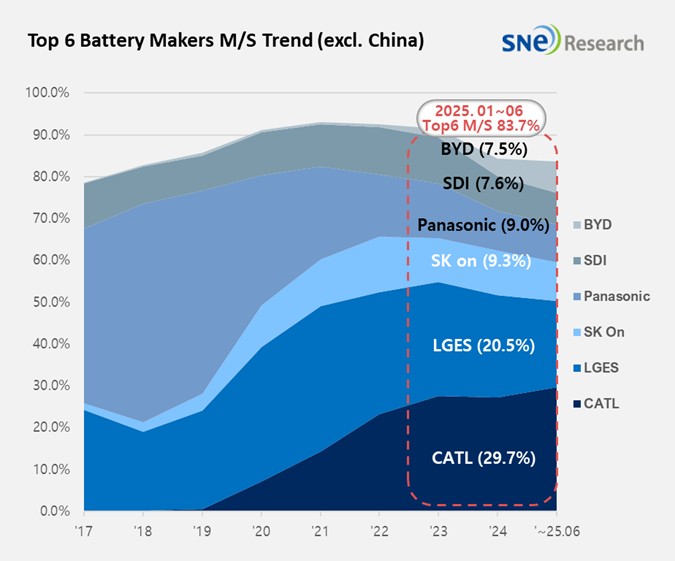

The combined market shares of LG Energy Solution, SK On, and Samsung SDI in global electric vehicle battery usage from Jan to June in 2025 posted 37.5%, a 8.1%p decline from the same period of last year. LG Energy Solution ranked 2nd with 2.2% (43.0GWh) YoY growth, while SK On took the 3rd position with 10.6% (19.6GWh) growth. On the other hand, Samsung SDI posted 7.8% (16.0GWh) degrowth.

(Source: Global EV and Battery Monthly Tracker – July 2025, SNE Research)

If we look at the usage of battery made by the K-trio in terms of the sales volume of models, Samsung SDI’s battery was mainly supplied to BMW, Audi, and Rivian. BMW has Samsung SDI’s batteries in its major electrified models such as i4, i5, i7, and iX, and among them, the best-selling i4 saw a decline in sales, which has led to a 5.0% YoY decrease in the usage of batteries sold to BMW. Although Rivian recorded stable sales of R1S and R1T in the US, the newly launched standard range trim, to which Gotion’s LFP batteries are installed, has lowered the share of batteries supplied by Samsung SDI to Rivian. On the other hand, as Audi started selling Q6 e-Tron, built on the PPE platform, the usage of batteries recorded an 8.8% YoY growth.

SK On’s battery was mainly installed to electric vehicles made by Hyundai Motor Group, Mercedes-Benz, Ford, and Volkswagen. Hyundai Motor Group saw a gradual recovery in sales of IONIQ 5 and EV 6 after facelift, leading to a similar recovery in installation quantity of SK On’s battery. Steady sales of VW ID.4 and ID.7 also contributed to an increase in the usage of battery made by SK On. On the other hand, a slowdown in sales of Ford’s F-150 Lightning, to which large-capacity batteries are installed, has led to a 13.4% YoY decrease in the usage of batteries supplied to Ford.

LG Energy Solution’s battery was mainly used by Tesla, Chevrolet, Kia, and Volkswagen. In the case of Tesla, the declining sales of models equipped with LG Energy Solution’s batteries led to a 41.1% YoY decrease in Tesla’s usage of LG Energy Solution’s batteries. On the other hand, favorable sales of KIA EV3 in the global market and expanded sales of Equinox, Blazer, and Silverado EV, to which the Ultium platform was applied, in the North American market were a major drive behind the growth of usage of batteries made by LG Energy Solution.

Panasonic, which mainly supplies batteries to Tesla, ranked 4th on the list with a battery usage of 18.8GWh. Panasonic has been accelerating the reshuffling of supply chain in response to the recently fortified US tariffs on the Chinese batteries and raw materials. To be specific, Panasonic is trying to lower its dependency on the Chinese materials, expand the procurement of local materials, and secure new material sources in order to increase the stability in battery production. These efforts are expected to lay a significant foundation for recovery in the usage of batteries made by Panasonic and maintaining its market share in the North American market.

In the global market excluding China, CATL remained top on the list with a 33.2%(62.1GWh) YoY growth. Not only local Chinese OEMs, but many of major global OEMs also adopt CATL’s batteries for their electric vehicles.

BYD ranked 6th in the non-China market, posting a 153.0%(15.7GWh) YoY growth. BYD, which manufactures both batteries and electric vehicles (BEV+PHEV) in-house, has been expanding sales of electric vehicles in various segments based on its strong price competitiveness. Not only in the Chinese domestic market but also in the overseas market, BYD has been rapidly solidifying its presence. In particular, BYD showed a notable expansion in the European market. In the 1st quarter of this year, the usage of BYD batteries in Europe recorded 6.0GWh, a 313.4% YoY increase.

(Source: Global EV and Battery Monthly Tracker – July 2025, SNE Research)

In the first half of 2025, the global battery market outside of China has been shaped by simultaneous shifts in regional demand structures and adjustments in electrification strategies among automakers. In North America, the slowdown in sales of large electric pickup trucks has renewed attention on compact and mid-size SUVs as well as plug-in hybrid vehicles (PHEVs). Similarly, in Europe, automakers are diversifying their portfolios beyond battery electric vehicles (BEVs) to improve price competitiveness and defend profitability. Meanwhile, demand is rapidly expanding in Southeast Asia and India, driven by affordable EV models and LFP-based batteries. In response to these trends, Korean battery manufacturers are pursuing customer-specific product strategies that include high-performance solutions, platform-optimized designs, and cost-effective offerings, aiming to balance market share retention with profitability. As the non-China battery market evolves, regional differentiation in strategic response is becoming increasingly critical not only due to regulatory factors, but also because of dynamic changes in real demand and OEM strategies.

[2] Based on battery installation for xEV registered during the relevant period.