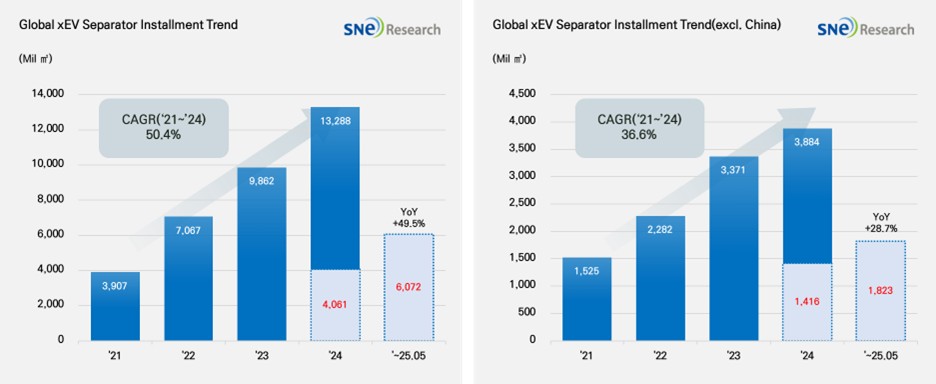

From Jan to May in 2025, Global[1] Electric Vehicle Separator Installment[2] Reached 6,072Mil ㎡, a 49.5% YoY Growth

- From Jan to May in 2025, the global

separator market posted a steady growth due to the increasing installment of

batteries in electric vehicles.

(Source: 2025 June Global EV & Battery Monthly Tracker (Incl. LiB 4 Major Materials), SNE Research)

From Jan to May in 2025, the total installment of separators used in electric vehicle (EV, PHEV, HEV) registered worldwide was approx. 6,072 Mil ㎡, posting a 49.5% YoY growth. Specifically, in the global market excluding China, the total installment of separators increased by 28.7%, reaching 1,823 Mil ㎡ and exhibiting a stable growth.

Separator is a key material which physically separates cathode and anode inside lithium-ion battery but at the same time enables lithium ions to move freely, playing an important role in determining the safety and performance of battery. With increasing demand for high-performance batteries in accordance with expansion of electric vehicle market, the separator market indeed has been growing rapidly.

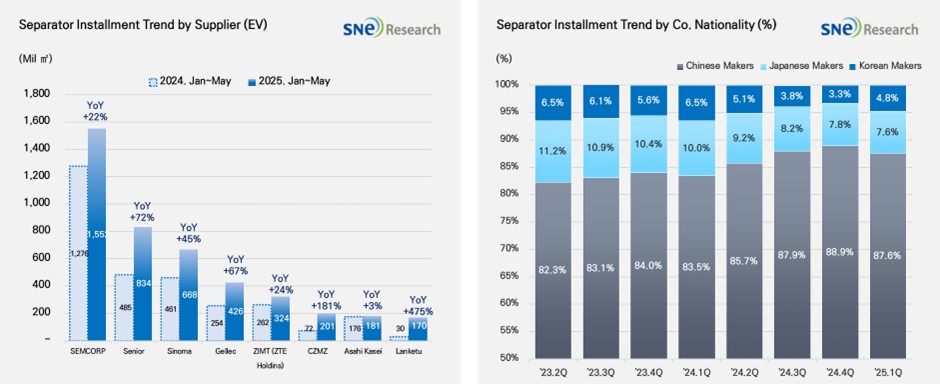

From Jan to May in 2025, major separator suppliers showed significant growth in the global separator market. In particular, SEMCORP’s separator was installed overwhelmingly more than others, reaching 1,552 Mil ㎡ and posting a 22% YoY growth. Other major Chinese companies such as Senior(+72%), Sinoma(+45%), and Gellec(+67%) also continued to exhibit a strong growth. Other than them, both ZIMT and CMZF have more than double-digit growth, expanding their shares in the market. On the other hand, SK IE Technology from Korea showed a noteworthy growth, reaching 166 Mil ㎡ and posting a 47% YoY growth.

In terms of market shares of companies by their nationality, the Chinese separator makers accounted for approx. 90% of the entire market share, almost dominating the market. Since the 2nd quarter of 2023, the market shares of Japanese and Korean separator companies have been continuously declining. In the 1st quarter of 2025, the Japanese separator makers took up 7.6%, and the Korean companies accounted for 4.8% of the market share. As the market dominance by the Chinese makers have intensified, the competition landscape has been further polarized between the Chinse makers and the non-China companies in the global separator market.

(Source: 2025 June Global EV & Battery Monthly Tracker (Incl. LiB 4 Major Materials), SNE Research)

Global separator makers have been actively expanding their local production bases in Europe and North America in response to strategic movements by OEMs who are trying to internalize the supply chain of batteries. The Korean and Japanese separator companies are strategically increasing their overseas production bases, and some of the Chinese makers are accelerating the establishment of global production network. As the US and Europe decided to impose restrictions on the use of Chinese materials in batteries, it has become an important challenge to secure separator suppliers outside China.

As the electric vehicle market has been growing rapidly, demand for separators has been sharply growing accordingly. The competitive landscape of separator market is expected to be continuously restructured in line with the evolution of battery technology and changes in strategies implemented by OEMs. Under this circumstance, global separator companies have been intensifying their investment to occupy a leading position in the market based on technology and product quality.

Specifically in the US, where related regulations have been revised to rule out the Chinese materials from the battery supply chain, the separator market has been moving towards one without any Chinese companies allowed to enter. Instead, SKIET’s separator, which is made outside of China, has been drawing attention from the industry as a strategic alternative. In future, not only the production site but also the origin of raw materials will become an important criterion, and whether companies pursue localization strategies will be a key factor in securing the mid- to long-term competitiveness of separator manufacturers.

[2] Based on batteries installed to electric vehicles registered during the relevant period.