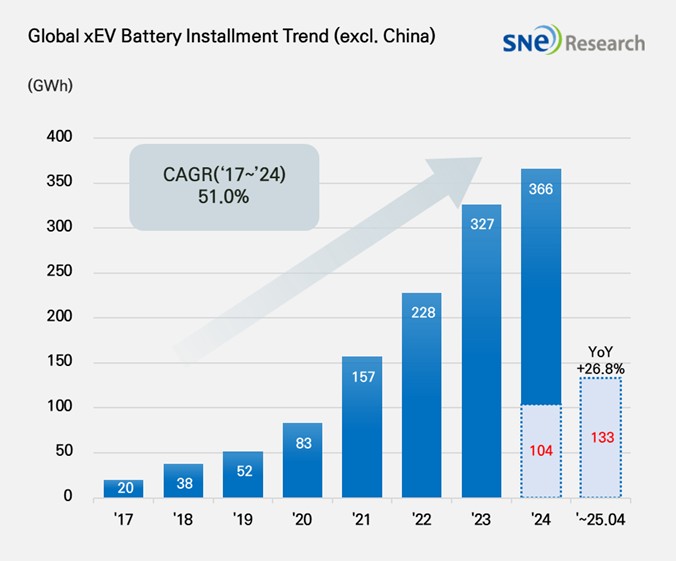

From Jan to Apr 2025, Non-Chinese Global[1] EV Battery Usage[2] Posted 132.6GWh, a 26.8% YoY Growth

-

From Jan to Apr 2025, K-trio’s combined M/S recorded 39.0% (except China market)

Battery installation for global

electric vehicles (EV, PHEV, HEV) excluding the Chinese market sold from Jan to

Apr 2025 was approximately 132.6GWh, a 26.8% YoY growth.

(Source: Global EV and Battery Monthly Tracker – May 2025, SNE Research)

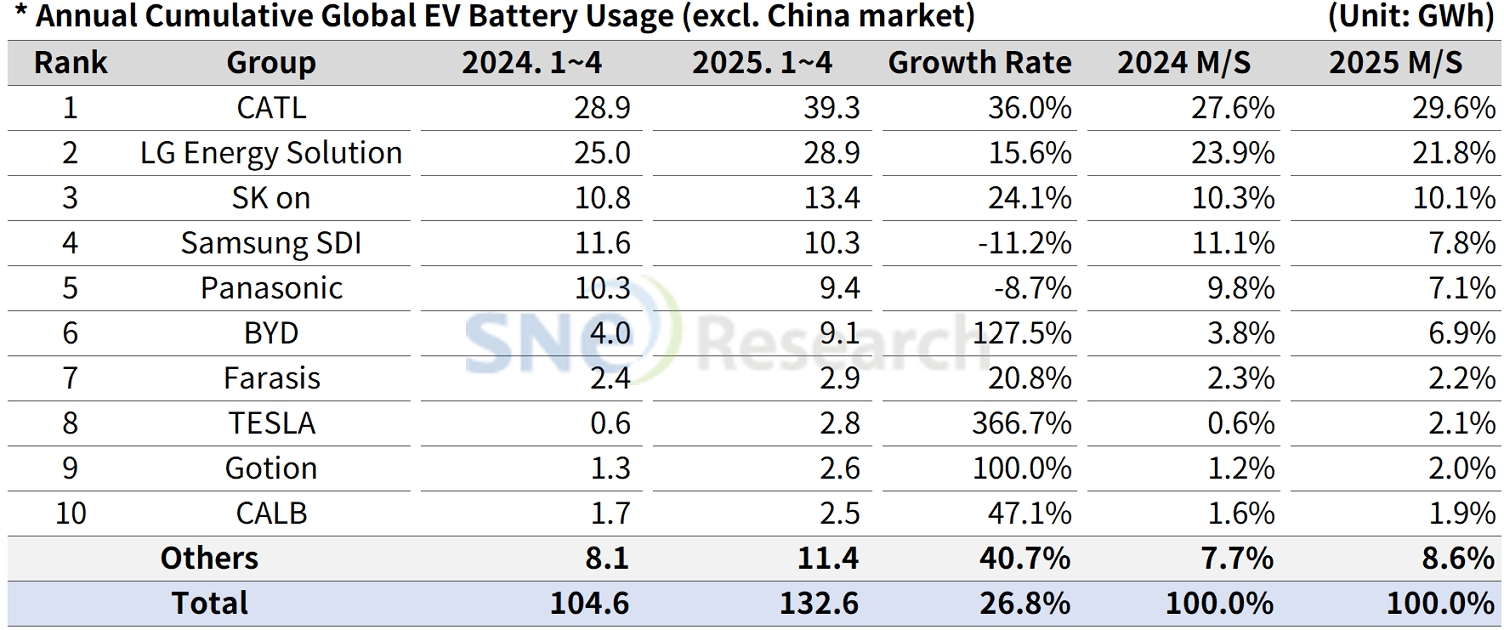

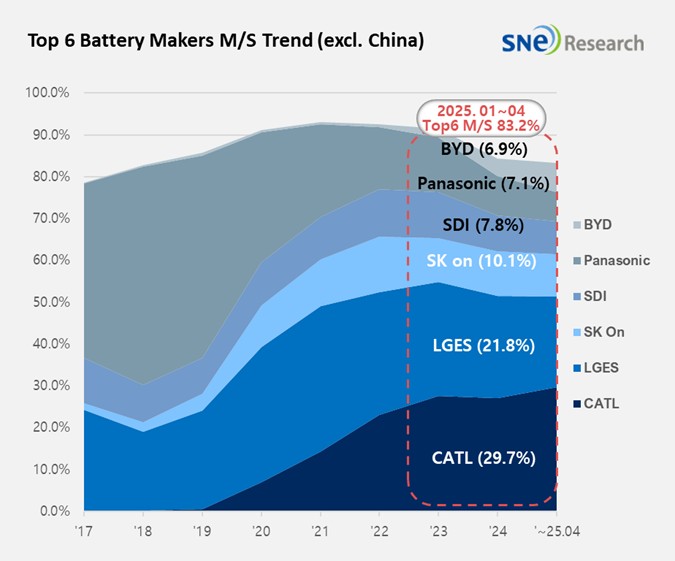

The combined market shares of LG Energy Solution, SK On, and Samsung SDI in global electric vehicle battery usage from Jan to Apr 2025 posted 39.7%, a 5.6%p decline from the same period of last year. LG Energy Solution remained 2nd on the list with 15.6%(28.9GWh) YoY growth, while SK On ranked 3rd with 24.1%(13.4GWh). On the other hand, Samsung SDI posted 11.2%(10.3GWh) degrowth. The downward trend in Samsung SDI’s battery usage was mainly caused by a decline in demand for batteries from major car OEMs in Europe and North America.

(Source: Global EV and Battery Monthly Tracker – May 2025, SNE Research)

If we look at the usage of battery made by the K-trio in terms of the sales volume of models, Samsung SDI’s battery was mainly used in BMW, followed by Audi and Rivian. BMW has Samsung SDI’s battery in its models such as i4, i5, i7, and iX, and among these, sales of i4 and i5 were favorable. On the other hand, even though Rivian posted a steady sale of R1S and R1T in the US, the release of standard-range trim with LFP battery, made by a battery maker other than Samsung SDI, had a negative impact on the installment volume of battery made by Samsung SDI. AUDI saw a decrease in sales of Q8 e-Tron as sales of Q6 e-Tron, to which PPE platform was installed, expanded, leading to a 6.2% decline in the usage of Samsung SDI’s battery in vehicles made by AUDI.

SK On’s battery was mainly installed in EV models made by Hyundai Motor Group, followed by Mercedes-Benz and Volkswagen. Hyundai Motor Group saw a recovery in sales after the facelifted version of IONIQ 5 and EV 6 were released. Ford saw a solid sale of F-150 Lightning, to which large-capacity battery is installed. Along with this, favorable sales of Volkswagen’s ID.4 and ID.7 had a positive impact on the increasing usage of battery made by SK On.

LG Energy Solution’s battery was mainly used by Tesla, followed by VW, Chevrolet, and Kia. In case of Tesla, the sales decline of models equipped with LG Energy Solution’s batteries led to a 23.3% decrease in Tesla’s usage of LG Energy Solution’s batteries. Meanwhile, the total usage grew by 146.4% due to favorable sales of VW’s ID series and Kia’s EV3 and the expanded sales of Chevrolet Equinox, Blazer, and Silverado EVs, which are built on the Ultium platform.

Panasonic, which supplies batteries mainly to Tesla, ranked 5th on the list with a battery usage of 9.4GWh which declined by 8.7%. Panasonic is currently working to restructure its supply chain in response to the recently strengthened U.S. tariffs on Chinese batteries and raw materials and is implementing a strategy to increase the proportion of local production within the North American region. In particular, Panasonic is focusing on reducing its dependence on Chinese materials and securing new materials while expanding local procurement to build a stable battery supply chain. These efforts are expected to lead to a recovery in battery usage and enhanced supply stability in the North American region in the future.

In the global market excluding China, CATL remained top on the list with a 6.0%(39.3GWh) YoY growth. Not only local Chinese OEMs, but many of major global OEMs also adopt CATL’s batteries for their electric vehicles.

BYD ranked 6th in the non-China market, posting a 127.5%(9.1GWh) YoY growth. BYD, which manufactures both batteries and electric vehicles (BEV+PHEV) in-house, is gaining significant popularity by introducing a variety of electric vehicles to the market, leveraging its strong price competitiveness. BYD is working to increase overseas production capacities and expand the supply chain in order to increase its overseas market share, especially actively engaging in promoting itself in the Korean and European markets.

(Source: Global EV and Battery Monthly Tracker – May 2025, SNE Research)

Meanwhile, the Chinse battery makers have been aggressively working to enter the European market and increasing investments in battery production in Europe, which posed a challenge to the Korean battery manufacturers. Major Chinese companies such as CATL and BYD are solidifying their cooperative ties with the European OEMs based on their price competitiveness and fast production, also posing a threat to the Korean companies who struggle to keep their market shares in the region. In response to this, the Korean battery manufacturers are accelerating the commercialization of next-generation battery technology and high-energy density batteries based on their technical competitiveness. Also, through the establishment of joint ventures and expansion of production capacities in Europe, they are working to secure stability in supply chain and reinforce their market responsiveness.

[2] Based on battery installation for xEV registered during the relevant period.