<2025> Fast Charging Technology Trends and Outlook for Secondary Batteries

On April

21, 2025, CATL unveiled its 2nd-generation Shenxing battery at ‘Super Tech

Day.’ Based on LFP chemistry, the battery enables up to 520 km of driving on a

5-minute charge and can charge from 5% to 80% in just 15 minutes even at –10°C.

CATL announced plans to equip the battery in over 67 EV models within 2025.

In March

2025, BYD introduced its 10C flash-charging Blade Battery, capable of

delivering approximately 470 km of range with just a 5-minute charge. Utilizing

silicon carbide (SiC) power chips and BYD's proprietary Blade Battery, the

system supports charging at up to ~1000V and 1MW. BYD plans to build over 4,000

ultra-fast charging stations across China. The charging speed surpasses Tesla’s

Supercharger and reduces EV charging time to a level comparable to fueling

internal combustion engine vehicles.

The

ultra-fast charging technologies developed by CATL and BYD are expected to

address key concerns over EV charging time and driving range, thereby

accelerating EV adoption. These technological advancements pose a significant

challenge for battery manufacturers in the U.S. and Europe.

China,

which holds the world’s largest charging infrastructure, plans to build a

network capable of supporting over 20 million EVs by 2025. The country is

introducing various charging methods, including battery swapping stations. As

of October 2024, a total of 11.88 million chargers have been installed, of

which 3.39 million are public chargers.

As of the

end of 2024, approximately 200,000 public charging ports are in operation in

the United States. EVgo plans to install 7,500 fast chargers rated at 350 kW

over the next five years. Through technological standardization, Tesla’s NACS

(North American Charging Standard) plug has been adopted as an SAE

international standard, and major automakers are now adopting it.

The EU aims

to install 3.5 million public charging points by 2030 and has mandated the

installation of fast charging stations at 60 km intervals along highways. As of

the end of 2023, more than 630,000 public chargers had been installed, and

approximately 410,000 new chargers need to be added annually to meet the

target. CCS (Combined Charging System) has been adopted as the primary

technical standard, and the deployment of high-power fast charging stations

(HPC) is expanding.

Meanwhile,

South Korea aims to install 1.23 million chargers by 2030, including 12,000 DC

fast chargers by 2025. As of the end of 2022, approximately 200,000 public

chargers had been installed, one of the highest levels globally. DC fast

chargers account for about 13% of the total, and the deployment of high-power

chargers is expected to increase going forward.

Going

forward, fast charging technology is expected to converge with solid-state

batteries, hybrid battery systems, ultra-high voltage charging systems (800V

and above), and wireless charging technologies, forming a new paradigm. Fast

charging technology for secondary batteries is not merely about charging speed;

it represents an integration of battery materials, design, and system

integration technologies. It is expected to play a pivotal role in accelerating

the adoption of electric vehicles and enhancing the overall competitiveness of

the battery-based energy industry.

Cathode

materials for fast charging must withstand high current densities during rapid

charging. Therefore, high-nickel NCM/NCA materials with higher nickel content

than conventional NCM622 or NCM811 are mainly used. To control oxidation

reactions that occur during fast charging, surface coating technologies—such as

Zr-, Al-, or Ti-based coatings—are also applied.

For anode

materials, there is a risk of lithium plating during fast charging. To address

this issue, silicon-based composite anodes (such as SiOx or Si–C composites)

are gaining attention. However, improvements in binders and surface

modification techniques are also being implemented to mitigate

expansion-related challenges.

Meanwhile,

electrolytes require high ionic conductivity for effective fast charging. To

achieve this, technologies such as high-concentration electrolytes (HCE, LHCE)

and additives (e.g., FEC, VC) are used to control SEI formation and enhance the

thermal stability of the electrolyte.

In

electrode design and structure, thin electrode designs or three-dimensional

structured electrodes are being applied to shorten the diffusion path of

lithium ions within the electrode. Optimization of conductive additives is also

used to minimize internal resistance. These structural improvements contribute

not only to reducing charging time but also to suppressing heat generation.

Thermal

management systems, whose importance has grown recently, address heat issues at

the battery cell level. A variety of technologies are being implemented,

including PCM (phase change material)-based cooling, liquid cooling systems,

and AI-based temperature prediction and control systems.

As of 2024,

the global EV charger market is estimated at approximately USD 22.45 billion

and is expected to reach USD 257 billion by 2032, with a CAGR of around 35.6%

(Fortune Business Insights).

This report

broadly covers the current status of battery fast charging, fast charging

technologies and trends, application of fast charging systems, and the

development of next-generation fast charging technologies. It includes detailed

information from basic principles to practical applications, offering valuable

insights for understanding and learning technologies related to both batteries

and chargers in the field of fast charging.

The

strong points of this report are as follows:

① Latest trends in fast

charging infrastructure

②

Development status of major battery OEMs for fast charging

technology

③ Domestic

and international policy and standardization trends for fast charging

④

Fast charging systems for devices ranging from small

electronics to drones, UAM, autonomous robots, and EVs

⑤ Next-generation

charging technologies and research trends, including wireless fast charging for

batteries

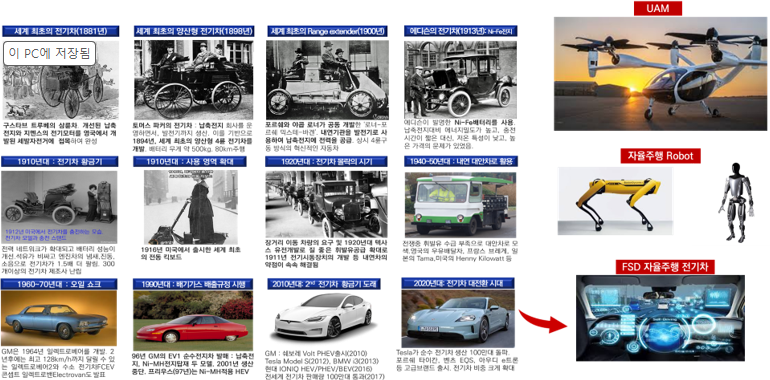

<History and Future of EV Development (UAM, Autonomous EVs, Robots)>

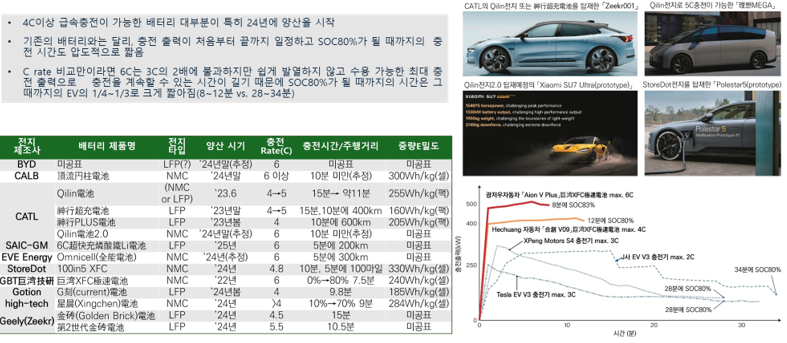

<High C-rate batteries: Start of mass production of batteries capable of charging in under 10 minutes and launch of EVs equipped with them>

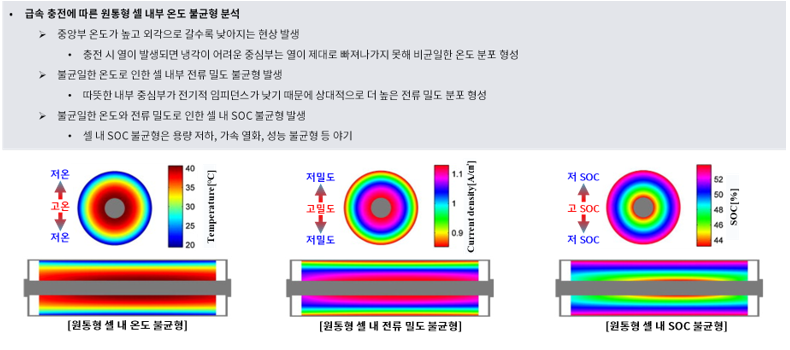

<Internal temperature

characteristics under fast charging – ① Cylindrical type>

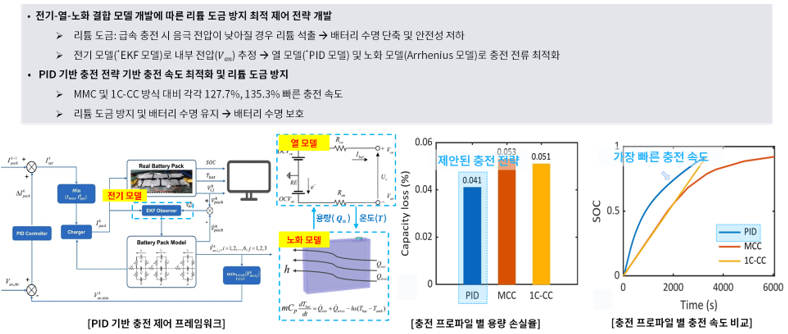

<Optimization study of battery pack fast charging to prevent lithium plating>

Contents

1. Battery Fast Charging Infrastructure and Development Status

1.1

Current Status of Battery Fast Charging 11

1.1.1 Status

Surrounding Fast Charging Infrastructure 11

1.1.1.1 History of EV Development and Future

Directions 11

1.1.1.2 History of EV Development and Charger

Development 12

1.1.1.3 Comparison of Major Charging Technologies 13

1.1.1.4 Survey Analysis of Charging Environment in

Korea 14

1.1.1.5 Survey Analysis of Charging Environment in

China 16

1.1.1.6 Status of Vehicles Based on China’s High-Voltage Fast Charging Platform 18

1.1.1.7 Status of China’s

High-Voltage Fast Charging Infrastructure 19

1.1.1.8 China’s High-Voltage

Fast Charging Support Policies 20

1.1.1.9 Survey Analysis of Charging Infrastructure

in the US 21

1.1.2 Status Surrounding Fast Charging Technologies 22

1.1.2.1 Start of Mass Production of Batteries

Supporting Charging (<10 min) and Launch of EVs Equipped with Them 22

1.1.2.2 High C-rate Batteries: Major Manufacturers

Overview 23

1.1.2.3 CATL Qilin Battery 24

1.1.2.4 Summary of Characteristics of CATL

2nd-Generation Shenxing Battery 26

1.1.2.5 BYD’s Ultra-Fast

Charging Technology 30

1.1.2.6 巨湾技硏(GBT) XFC

Ultra-Fast Charging Battery Cell 31

1.1.2.7 巨湾技硏(GBT) XFC

Ultra-Fast Charging Battery Cell Roadmap 34

1.1.2.8 CATL Qilin Battery (Composite Current Collector:

MPCC) 35

1.1.2.9 Introduction of Porous Current

Collector (PCC) 36

1.1.2.10 High C-rate Batteries:

Application of Porous Current Collector (PCC) Sheet (Murata) 37

1.1.2.11 High C-rate Batteries:

Comparison of Fast Charging Batteries 38

1.1.2.12 BYD Ultra-Fast Battery

Technology 40

1.1.2.13 Ultra-Fast Charging Technology:

Emergence of 1MW Maximum Power 41

1.1.2.14 Status of Charging Services by

Major Countries 42

1.1.2.15 Global EV Charger Market Outlook

43

1.1.2.16 Status of Charging Services by

Major Countries: Japan 44

1.1.2.17 Beginning of Global Ultra-High Power Charging 48

1.1.2.18 Introduction of Ultra-High Power Chargers in Japan 49

1.1.2.19 DWPT Demonstration at

Osaka-Kansai Expo in Japan 50

1.2

Overview of Battery Charging Basics 53

1.2.1 Basic Structure

and Charging Principles of Lithium-Ion Batteries 53

1.2.1.1 Charging Principles of Lithium-Ion Batteries

53

1.2.2 Charging Methods of Lithium-Ion Batteries 54

1.2.2.1 Constant Current - Constant Voltage Charging

54

1.2.2.2 Multi-Stage Constant Current Charging 55

1.2.2.3 Constant Power - Constant Voltage Charging

56

1.2.2.4 Constant Temperature Constant Voltage

Charging 57

1.2.2.5 Boost Charging 58

1.3 Design of Battery

Fast Charging Technology 59

1.3.1 Overview of

Fast Charging Technology 59

1.3.1.1 Necessity of Battery Fast Charging 59

1.3.1.2 Issues from Applying Battery Fast Charging

61

1.3.2 Design Strategies for Fast Charging Technology

63

1.3.2.1 Considerations in Designing Battery Fast

Charging Strategies 63

1.3.2.2 Design Strategies for Battery Fast Charging

Profiles 64

1.4

Electrochemical Property Analysis Based on Battery Fast Charging 70

1.4.1 Changes in

Internal Properties by Material 70

1.4.1.1 Changes in Internal Properties Under Fast

Charging – (1) NMC 70

1.4.1.2 Changes in Internal Properties Under Fast

Charging – (2) LFP 71

1.4.1.3 Changes in Internal Properties Under Fast

Charging – (3) LTO 73

1.4.2 Changes in Internal Properties by Cell Format 74

1.4.2.1 Changes in Internal Temperature Properties

Under Fast Charging – (1) Cylindrical 74

1.4.2.2 Changes in Internal Temperature Properties

Under Fast Charging – (2) Pouch 76

1.4.2.3 Changes in Internal Temperature Properties

Under Fast Charging – (3) Prismatic 77

1.4.2.4 Battery Fast Charging Infrastructure and

System Requirements – Output 78

1.5

Requirements for Battery Fast Charging 79

1.5.1 Battery Fast

Charging Infrastructure and System Requirements 79

1.5.1.1 Infrastructure Expansion 79

1.5.1.2 Power 80

1.5.1.3 ESS 81

1.5.1.4 V2G 82

1.5.1.5 Communication Systems 83

1.5.1.6 Safety 84

1.5.1.7 Optimization of Charging Speed and Power

Consumption 85

2.

Battery Fast Charging Technology

2.1 Overview of

Battery Charging Technology 87

2.1.1 On-Board Battery Charging 87

2.1.1.1 Overview of On-Board Charging Technology 87

2.1.1.2 Structure of On-Board Charging Systems 89

2.1.1.3 Advantages and Disadvantages of On-Board

Charging Technology 91

2.1.2 Off-Board Battery Charging 92

2.1.2.1 Overview of Off-Board Charging Technology 92

2.1.2.2 Structure of Off-Board Charging Systems 94

2.1.2.3 Advantages and Disadvantages of Off-Board

Charging Technology 97

2.1.2.4 Application Cases of Off-Board Charging 98

2.2 Structure and Principles of Battery Charging Systems 100

2.2.1 Hardware Configuration and Structure of

On-Board Charging Systems 100

2.2.1.1 Overview of On-Board Charging Systems 100

2.2.1.2 Hardware Structure of On-Board Charging

Systems 101

2.2.2 Operating Principles of On-Board Charging

Systems 110

2.2.2.1 Operating Concepts of On-Board Charging

Systems 110

2.2.2.2 Protective Control Technology in On-Board

Charging Systems 112

2.2.3

Hardware Configuration and Structure of Off-Board Charging Systems 115

2.2.3.1 Overview of

Off-Board Charging Systems 115

2.2.3.2 Hardware Configuration of Off-Board Charging

Systems 116

2.2.3.3 Hardware Structure of Off-Board Charging

Systems 117

2.2.4 Operating Principles of Off-Board Charging Systems 124

2.2.4.1 Operating Concepts of Off-Board Charging

Systems 124

3.

Battery Fast Charging Technology Trends

3.1 Domestic and

Global Trends in Fast Charging Technology 130

3.1.1 Status of Domestic and Global Fast Charging

Market Infrastructure 130

3.1.1.1 Status of Domestic Fast Charging

Infrastructure 130

3.1.1.2 Status of Overseas Fast Charging

Infrastructure 131

3.1.2 Overview of Domestic and Global Fast Charging

Technologies 132

3.1.2.1 QC (Quick Charge) Technology 132

3.1.2.2 USB Power Delivery (USB PD) Charging

Technology 139

3.1.2.3 GaN (Gallium Nitride)-Based Charging

Technology 147

3.2

Domestic and Global Fast Charging Technology Policy and Standardization Trends

152

3.2.1 Necessity of

Fast Charging Infrastructure and Standardization 152

3.2.1.1 Necessity and Current Status of Expanding

Fast Charging Infrastructure 152

3.2.1.2 Necessity of Standardizing Fast Charging

Infrastructure 153

3.2.2 Domestic and Global Fast Charging Technology

Standards and Regulatory Trends 155

3.2.2.1 Introduction to Domestic and Global Fast

Charging Technology Standards 155

3.2.2.2 Application Trends of EV Fast Charging

Technology Standards 156

3.2.2.3 Status of Standards and Regulations for Fast

Chargers 160

3.2.3 Domestic and Global Policies and Support

Measures for Fast Charging Technology Development 163

3.2.3.1 Domestic Policies and Support Measures for

Fast Charging Technology Development 163

3.2.3.2 Overseas Policies and Support Measures for

Fast Charging Technology Development 164

3.2.4 Domestic and Global Fast Charging Technology

Patent Trends 167

3.2.4.1 Status of Domestic and Global Patent

Applications 167

3.2.4.2 Issues in Fast Charging Technology Patents

168

4.

Application of Battery Fast Charging Systems

4.1 Battery Fast

Charging Systems for Small Applications 170

4.1.1 Development of Charging Systems for Small

Applications 170

4.1.1.1 Overview and Development Background of Small

Applications 170

4.1.1.2 Advancement of Fast Charging Technologies

and Protocol Innovation 171

4.1.1.3 Optimization of Fast Charging Systems and

Technologies 173

4.1.1.4 Development of Technologies for Battery Life

Management and Safety Improvement 174

4.1.2 Structure and Application Cases of Fast

Chargers for Small Applications 175

4.1.2.1 Fast Charging Requirements for Small

Applications 175

4.1.2.2 Hardware of Fast Chargers for Small

Applications 176

4.1.2.3 Software of Fast Chargers for Small

Applications 177

4.1.2.4 Application Cases of Fast Chargers for Small

Applications 178

4.1.3 Development Trends of Fast Charging Systems for

Small Applications 179

4.1.3.1 Development Trends of Smartphone Charging

Systems 179

4.1.3.2 Development Trends of Small Mobility

Charging Systems 182

4.1.3.3 Development Trends of Small Drone Charging

Systems 183

4.1.3.4 Development Trends of UAV Charging Systems

184

4.1.3.5 Development Trends of Autonomous Robot

Charging Systems 185

4.1.3.6 Batteries for Autonomous Robots 188

4.1.3.7 Batteries for Quadruped and Humanoid Robots

189

4.1.3.8 Market Outlook for Autonomous Mobile Robots

(AMR) 190

4.2 Battery Fast

Charging Systems for Mid/Large Applications 191

4.2.1 Development of Charging Systems for Mid/Large

Applications 191

4.2.1.1 Overview and Development Background of

Mid/Large Applications 191

4.2.1.2 Transition from Initial Charging

Technologies to Ultra-Fast Charging 193

4.2.1.3 Key Elements of High-Voltage, High-Power

Charging Technologies 194

4.2.1.4 System Integration and Infrastructure

Optimization 195

4.2.1.5 Advancement and Development of Mid/Large

Charging Systems 196

4.2.1.6 Infrastructure Construction and Economic

Feasibility 197

4.2.2 Structure and Application Cases of Fast

Chargers for Mid/Large Applications 198

4.2.2.1 Fast Charging Requirements for Mid/Large

Applications 198

4.2.2.2 Hardware of Fast Chargers for Mid/Large

Applications 199

4.2.2.3 Software of Fast Chargers for Mid/Large

Applications 202

4.2.2.4 Application Cases of DC Fast Charging

Systems (Domestic) 204

4.2.2.5 Application Cases of DC Fast Charging

Systems (Overseas) 206

4.2.2.6 Application Cases of Supercapacitor-Based

Charging Systems 208

4.2.3 Development Trends of Fast Charging Systems for

Mid/Large Applications 214

4.2.3.1 Development Trends of EV Charging Systems

214

4.2.3.2 Development Trends of Electric Ship Charging

Systems 218

4.2.3.3 Development Trends of Mid/Large Personal

Mobility Charging Systems 219

5.

Development Trends of Next-Generation Fast Charging Technologies

5.1 Battery

Wireless Charging Technologies 221

5.1.1 Necessity of Wireless Charging Technologies

221

5.1.1.1 Evolution of Charging Methods with the

Spread of Next-Generation Mobility 221

5.1.1.2 Issues of Wired Charging Systems 222

5.1.2 Basic Principles and Components of Wireless

Charging Technologies 223

5.1.2.1 Basic Principles of Wireless Charging 223

5.1.2.2 Components of Wireless Charging Systems 225

5.1.2.3 Issues and Improvements in Wireless Charging

Efficiency and Safety 226

5.1.3 Major Wireless Charging Methods 228

5.1.3.1 Magnetic Inductive Method 228

5.1.3.2 Magnetic Resonance Method 230

5.1.3.3 Hybrid Wireless Charging Methods 233

5.1.4 Development Trends of Wireless Charging

Technologies in Battery Applications 235

5.1.4.1 Development Trends of Wireless Charging

Technologies for Small Applications 235

5.1.4.2 Development Trends of Wireless Charging

Technologies for Mid/Large Applications 240

5.1.4.3 Research Trends in Wireless Charging

Technologies (DWPT Demonstration Projects, Trends in Korea-Japan-Overseas

Companies) 244

5.1.4.4 Future Prospects and Challenges of Wireless

Charging Technologies 258

5.2

Battery Fast Charging Technology Research Trends 259

5.2.1 New

Technologies for High-Power Charging (HPC) 259

5.2.1.1 Optimization of Integrated Circuit Topology

for High-Power Charging 259

5.2.1.2 Liquid-Cooled Cable Optimization Based on

Optimal Cable Core Structure Design 260

5.2.1.3 Research on Improving Fast Charging

Efficiency Through DC/DC Converters 261

5.2.2 Optimization Technologies for Fast Charging

Profiles 262

5.2.2.1 Research on Battery Pack Fast Charging

Optimization to Prevent Lithium Plating 262

5.2.2.2 Reinforcement Learning-Based Optimization of

Fast Charging Profiles 263

5.2.2.3 Battery Fast Charging Technologies Based on

Multi-Stage Charging Strategies 264

5.2.2.4 Fast Charging Technologies Based on Adaptive

CC-CV Profiles 265

5.2.2.5 Fast Charging Technologies Based on MCC-CV +

Pulse Integrated Profiles 266

5.2.3

Battery Materials and Electrode Technologies for Fast Charging 267

5.2.3.1 Research on

Ultra-Fast Charging Based on Anode Material Improvement 267

5.2.3.2 Enhancement of Fast Charging and

Low-Temperature Charging Performance Using Li₃PO₄

268

5.2.3.3 Epitaxial

Entropy Coating (EEC) Strategy Based on Ultra-High Nickel (Ni) Cathode 269

5.2.3.4 Development of Binder-Free Lithium-Ion

Battery Cathodes for Fast Charging 270

5.2.3.5 High-Performance LIB for UAM Fast Charging:

Application of Si-Based Anode 271

5.2.3.6 Development of Battery Electrolytes via

Controlled Solvation Structure Design 272

5.2.3.7 Development of Optimized Electrodes by Mg

Doping in LCO 273

5.2.3.8 Improvement of Fast Charging Performance in

BaTiO₃-Composite

LFP/C Electrodes 274

5.2.4 Safety and Thermal Management Technologies for Fast Charging

275

5.2.4.1 Development of Hybrid Single-Phase Immersion

Cooling Structures for Battery Thermal Management 275

5.2.4.2 Combination of Thermal Switching and

Self-Heating Methods 276